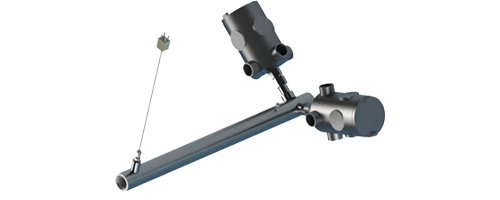

Custom Threaded Inline Heaters

Max temperature up to 1652ºF / 900ºC

Style A – Leak-proof design with sealed feedthrough, suitable for high-pressure systems

Style B – Flexible wire leads, suitable for moderate pressure systems. Some leakage will occur at wires.

Power 6kW — 8kW, voltage 208/240V

CE, RoHS

High-Performance, Leak-Proof Air Heating Solutions for High Temp Applications

The TUTCO SureHeat Hi-Temp Threaded Inline Heater is engineered to provide precise, efficient, and reliable air heating for demanding industrial environments. Capable of reaching exhaust temperatures up to 1,652°F (900°C) and designed to withstand inlet pressures up to 100 PSI, this heater is ideal for applications that require rapid, high-temperature airflow in confined or challenging spaces. Its robust stainless steel construction, versatile NPT mounting options, and compatibility with digital temperature controllers make it a dependable choice for processes where accuracy, repeatability, and durability are critical. Whether integrated into OEM machinery, production lines, or standalone systems, the Threaded Inline Heater delivers consistent, high-performance heat that outperforms conventional inline air heaters.

Discover which Threaded Inline heater is ideal for your application

Hi-Temp Style A

For higher pressures and higher inlet temperatures

| Max Exit Temp | 1652ºF (900ºC) |

| Max Inlet Temp | 1000ºF (538ºC) |

| Max Static Pressure | 100 PSI (7 Bar) |

| Thermocouple Probe | Duplex Type K |

| Minimum Airflow | 3 SCFM (85 SLPM) |

Hi-Temp Style B

For lower pressures and lower inlet temperatures

| Max Exit Temp | 1652ºF (900ºC) |

| Max Inlet Temp | 120ºF (50ºC) |

| Max Static Pressure | 45 PSI (3 Bar) |

| Thermocouple Probe | 45 PSI (3 Bar) |

| Minimum Airflow | 3 SCFM (85 SLPM) |

Style A: Leak-Proof Design for High-Pressure Systems

- Leak-Proof Power Feedthrough: Features high-pressure power feedthroughs, ensuring a sealed electrical connection that prevents air leakage, making it ideal for pressurized systems.

- Maximum Inlet Temperature: Supports inlet temperatures up to 1000°F (538°C), suitable for high-temperature applications.

- Pressure Rating: Designed to withstand up to 100 PSI, accommodating high-pressure air systems.

- Electrical Termination: Equipped with nickel terminal posts, providing a secure and reliable electrical connection.

Style B: Flexible Wire Leads for General Applications

- Flexible Wire Leads: Comes with 12-inch flexible wire leads (12 AWG, fiberglass sleeved), offering ease of installation and flexibility in mounting.

- Maximum Inlet Temperature: Supports inlet temperatures up to 120°F (50°C), suitable for lower-temperature applications.

- Pressure Rating: Rated for up to 45 PSI, accommodating moderate-pressure air systems. Some leakage will occur at wires.

- Electrical Termination: Features stranded wire leads, allowing for flexible installation options.

Features & Benefits

- High-Temperature Performance: Achieves exhaust temperatures up to 1,652°F (900°C), suitable for processes like adhesive curing, plastic welding, and testing.

- High-Pressure Capability: Rated for inlet pressures up to 100 PSI, making it suitable for compressed air systems and high-pressure applications.

- Durable Construction: Housed in a 316 stainless steel body, offering corrosion resistance and long-term durability.

- Versatile Mounting Options: Available in 1-1/4" NPT compatible with standard industrial piping systems.

- Compatibility with Digital Controllers: Designed to integrate seamlessly with digital temperature controllers featuring Type K thermocouple inputs, enabling precise temperature regulation.

Specifications

- Maximum Exhaust Temperature: Up to 1,652°F (900°C)

- Maximum Inlet Pressure: 100 PSI (Style A), 45 PSI (Style B)

- Material: 316 Stainless Steel

- Mounting Style: Threaded NPT (1-1/4")

- Electrical Termination Style A: Terminal Posts, Style B: Wire Leads

- Power Options: 6kW or 8kW

- Voltage Options: 208V, 240V

- Control Compatibility: Compatible with digital controllers with Type K thermocouple inputs

Industries & Applications

The TUTCO SureHeat Threaded Inline Heater is engineered for precision air heating in a wide range of industrial and OEM applications. Its high-temperature capability, robust pressure rating, and versatile mounting options make it suitable for both localized and high-volume process heating needs.

- Automotive & Transportation – Adhesive activation, panel bonding, heat forming, welding, testing, and simulation. Ensures strong, durable bonds in assembly processes and consistent heat for component testing.

- Aerospace & Defense – Composite curing, component testing, thermal simulations, de-icing systems, and other high-temperature processes where reliability and precision are critical.

- Plastic Processing & Packaging – Plastic welding, shrink fitting, forming, bending, sealing, and heat shrinking applications. Provides controlled heat for improved product quality and process efficiency.

- Electronics & Semiconductor – Solder reflow, wafer processing, quick drying, component sealing, and curing adhesives. Maintains uniform heat in sensitive manufacturing environments.

- Food & Beverage – Drying, sterilization, baking, coating, and shrink-wrapping processes. Supports consistent product quality while meeting hygiene standards.

- Medical & Pharmaceutical – Sterilization, packaging, lab testing, and other processes requiring precise, high-temperature air in controlled settings.

- Printing & Converting – Ink drying, laminating, coating, embossing, and shrink wrapping. Enhances production efficiency with accurate, repeatable heating.

- General Industrial & OEM Machinery – Hot air knives, small-scale curing, drying tunnels, and integration into custom machinery requiring high heat. Offers versatility for both standalone and integrated heating systems.

Make sure to properly mount the TC coupling so that the TC is slightly above the ceramic rod running through the center of the Serpentine™ heating element. The open end of the TC should be in the heated air stream. The inlet side of the heater is located closest to the power feed throughs. Installation orientation is critical. Positioning the heater in the wrong direction will cause damage. Like all Tutco SureHeat heaters, do not operate without the air on.

Notes

Threaded In-line thermocouple adapter material is 316 stainless steel. Better resistance to oxidation at higher temperatures. Type K thermocouple F206119 sold separately. Use of other sensor types and mounting locations can result in heater damage. Thermocouple mounting depth location is critical. Follow all mounting instructions. If replacing a Thermocouple, take note of the depth by measuring the distance to the compression fitting on the old Thermocouple.

Comparison with Competitors

The Threaded Inline Heater’s robust design, high-pressure capability, and compatibility with digital temperature controllers make it an ideal solution for any process that demands precise, repeatable, and efficient high-temperature airflow, outperforming conventional heaters and other inline alternatives. TUTCO SureHeat Threaded Inline Heater offers several advantages:

- Higher Temperature Capability: Competitors like the Leister LE Mini offer maximum temperatures up to 900°F (482°C), whereas the SureHeat model reaches 1,400°F (760°C), providing greater flexibility for high-temperature processes.

- Leak-Proof Design: The Style A configuration of the SureHeat heater ensures a sealed electrical feedthrough, preventing leaks in sensitive or pressurized systems, a feature not commonly found in competitor models.

- Durability: Constructed from 304 stainless steel, the SureHeat heater offers superior corrosion resistance and longevity compared to some competitors that may use less durable materials.

- Pressure Rating: With a maximum inlet pressure of 150 PSI, the SureHeat heater is suitable for high-pressure applications, whereas many competitors are rated for lower pressures.

- Versatility: Available in multiple NPT sizes and power options, the SureHeat heater can be tailored to specific application requirements, offering more customization than some competitor models.

Closed-Loop (Feedback) Control

Closed-loop heater control systems use a power controller, temperature controller and thermocouple to monitor and provide a constant output temperature, regardless of changes in airflow. The typical temperature controller provides a convenient display of the air temperature. (not the element temperature)

Power Controller

SCR (Silicon Controlled Rectifier) power controls will provide the smoothest power regulation for electric air heaters. Please contact Tutco SureHeat before using other power controllers, such as SSR (Solid State Relays) or other fast-switching controllers.

Temperature Controller

Use only digital temperature controls with Type K thermocouple inputs. The temperature control output must match the input of the power control (i.e., 4-20mA or 0-10VDC). A standard PID-type control with a wide proportional band setting will work best to minimize temperature overshoot. PID parameters may be auto-tuned, but only at temperature specifications below the maximum of the heater. Monitor the heater temperature rise and turn power off immediately if it rises above the heater specification during the auto-tune cycle. Thermocouple Use only a fine wire (0.030” max. wire diameter), exposed junction, Type K thermocouple placed within 1” of the heater exit for accurate temperature readings. Other thermocouple styles, or varying the distance from the heater exit, will result in temperature measurement errors and thus the potential for heater failure

Resources

Why choose TUTCO SureHeat

Industry Expertise: With decades of experience in industrial heating solutions, TUTCO SureHeat is a trusted name in the industry.

Reliable Performance: Our heaters are designed for consistent, repeatable results, ensuring quality and efficiency in your processes.

Comprehensive Support: We offer technical support, custom solutions, and integration assistance to meet your specific needs.

Global Reach: Our products are used worldwide, providing proven solutions in various industries.

The TUTCO SureHeat HT Threaded Inline Heater stands out in the market for its high-temperature capability, leak-proof design, and durable construction, making it an excellent choice for industrial applications requiring precise and reliable air heating. Whether you're integrating it into OEM equipment or using it in standalone applications, this heater offers the performance and versatility needed to meet your heating requirements.

Frequently Asked Questions

Compared to competitors, the SureHeat model delivers higher temperatures (up to 1,652°F/900°C), superior leak-proof performance in Style A, robust stainless steel construction for long-term durability, and flexible mounting options. Its high-pressure capability and compatibility with digital controllers make it a versatile and reliable choice for precise, high-temperature air heating applications.

Correct heater orientation is essential. The thermocouple should be mounted slightly above the ceramic rod in the serpentine heating element, with the open end in the air stream. The inlet side is closest to the power feedthroughs. Always operate the heater with airflow running; failure to do so can damage the unit. Threaded mounting ensures secure, leak-resistant installation.

Style A features a leak-proof power feedthrough and is rated for high-pressure systems (up to 100 PSI) with inlet temperatures up to 1,000°F (538°C), making it ideal for pressurized or high-temperature air systems. Style B has flexible wire leads and is designed for moderate-pressure systems (up to 45 PSI) with lower inlet temperatures (up to 120°F/50°C). Choose based on your system’s airflow, pressure, and installation flexibility requirements.

The SureHeat Threaded Inline Heater is engineered to handle exhaust temperatures up to 1,652°F (900°C), making it ideal for demanding processes such as adhesive curing, plastic welding, and composite testing. Its stainless steel construction, high-pressure rating, and precise temperature control capabilities ensure reliable performance even in challenging industrial environments.